- Passion intelligent warehouse logistics centralized control platform adopts Passion intelligent prospective flexible design concept and AI algorithms to connect logistics equipment in the plant and cover information island of each step of material, avoiding sluggish raw materials and guaranteeing the consistency of account and stock, realizing the maximization of the whole factory logistics equipment operation and assisting enterprises in reducing costs, improving efficiency and making wise decisions.

- It covers all functional modules required by warehouse management, such as personnel authority management, approval process, validity period management, stagnant material, high and low water level, warehousing and other modules, providing accurate data support for management decisions.

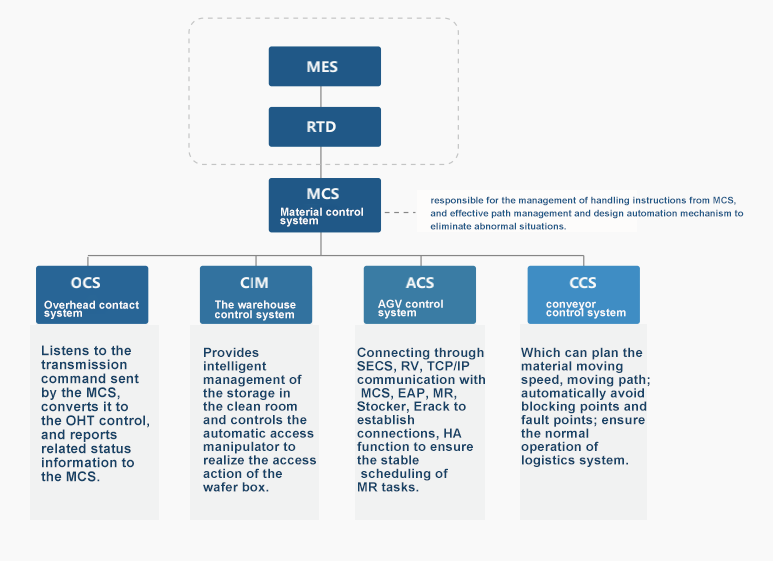

MCS:Material control system, responsible for managing the handling instructions from MCS, carrying out effective path management and designing automation mechanism to eliminate abnormal situations.

OCS:Overhead contact system, listens to the transmission command sent by the MCS, converts it to the OHT control, and reports related status information to the MCS.

CIM:The warehouse control system provides intelligent management of the storage in the clean room and controls the automatic access manipulator to realize the access of the wafer box.

ACS:AGV control system, connecting through SECS, RV, TCP/IP communication with MCS, EAP, MR, Stocker, Erack to realize HA function and ensure the stable scheduling of MR tasks.

CCS: conveyor control system, which can plan the material moving speed, moving path; automatically avoid blocking points and fault points; ensure the normal operation of logistics system.

No. 28 Heshun Road, Suzhou Industrial Park, China

No. 28 Heshun Road, Suzhou Industrial Park, China  +86 13451983657

+86 13451983657  sales@passioniot.com

sales@passioniot.com