Intelligent assembly station solution

Assembly station affects the labor intensity, work efficiency and production quality of assembly operation. Especially in the production process, how to avoid wrong and missing assembly and other operational errors, achieve a fool-proof assembly operations with better efficiency

Intelligent perception interactive and collaborative workstation

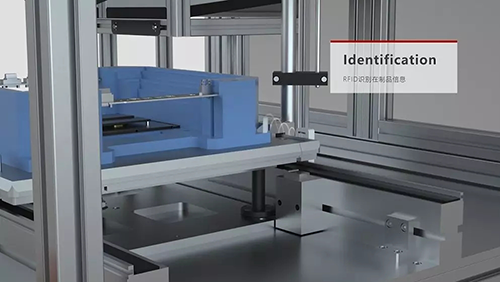

Facing the field of assembly manufacturing,the Intelligent perception interactive and collaborative workstation combines ergonomics and lean production concept is equipped with functions such as RFID automatic identification, acoustic-optical guidance fool-proof operation, automatic perception for error prevention, and interactive tablet for station operation, so as to realize cooperative operation of human, machine and material and ensure accurate, efficient and convenient assembly process.

Features of intelligent assembly stations

1. PVR material picking and detection grating and multi-light axis automatic induction to realize lighting guided picking, lighting guided sequential assembly, fool proof; 2. Using CBS wireless intelligent calling,even if the communication distance is long, it can ensure stable data transmission and help you realize the coordination of people, machines, materials and effectively improve the efficiency of workers through the wireless transmission of information; 3. After entering the assembly, the industrial tablet computer will display WIP information, material information and assembly operation instructions, and new employees can also work without training. IP series industrial tablet computers with efficient cooling system bring field operators and managers a better use experience; 4. Torque tightening gun guide shaft precise positioning, laser to guide installation, personnel rely on the system to automatically obtain the product assembly required torque value for assembly operations which can prevent fools and mistakes.

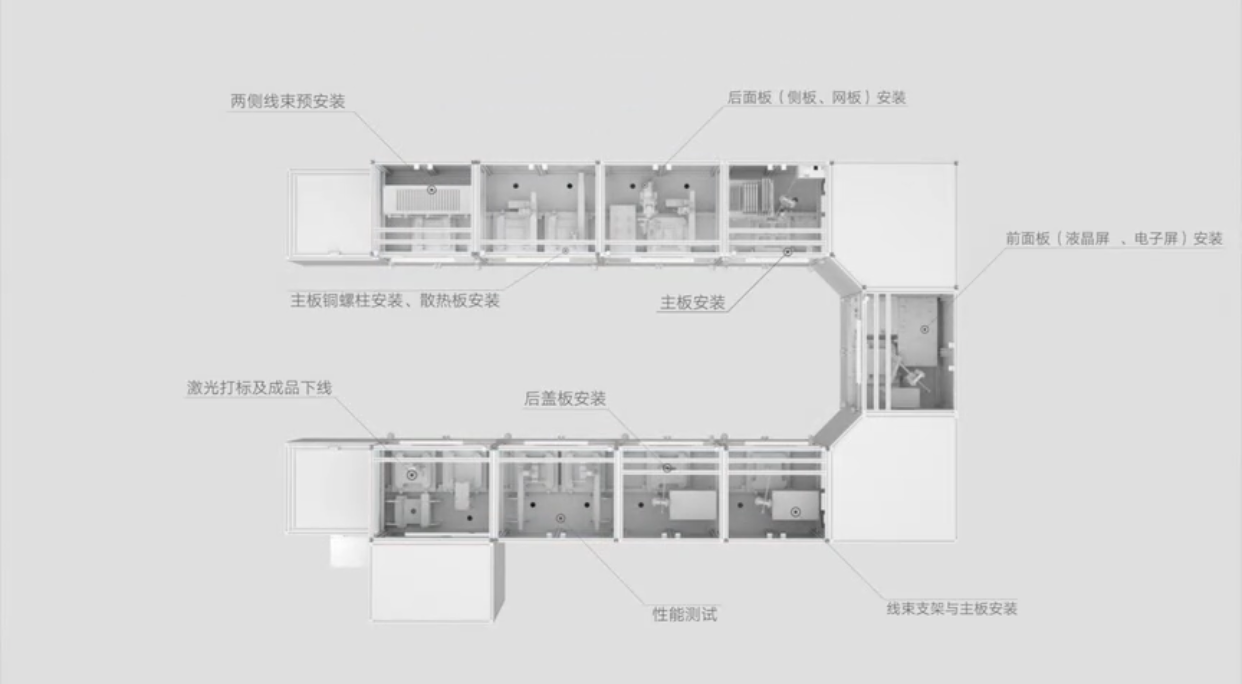

Operation process

WIP products enter the station with the tooling tray for assembly. At this point, RFID will automatically identify WIP and the industrial tablet will display the assembly information of WIP. After the assemblys process starts, the industrial tablet computer will display the product information of WIP, assembly material information and assembly operation instructions, so that the assemblers can carry out correct assembly operations according to the assembly guidance instructions. The grating automatically lights up to guide the operator to pick up the material.

Assembly process

In the assembly process, according to the actual situation of product material assembly, the operator can obtain material information by scanning the material bar code. The industrial tablet will display the current material information,the system obtains the assembly record,and the laser guides positioning for the next round of assembly. If abnormal assembly problems such as quality issues occur, the operator can press the CBS wireless intelligent call button to make an abnormal call. At the same time, the red light of the industrial signal indicator turns on and the industrial tablet displays error information. Operators will receive the information through the wireless device, confirm and go to the station to handle the abnormality. After the processing, the operator will press the CBS button to release the abnormality, and the station operator will resume normal assembly. When the assembly work in this link is completed, touch the interactive indicator light, and the operator will press the interactive indicator button.

No. 28 Heshun Road, Suzhou Industrial Park, China

No. 28 Heshun Road, Suzhou Industrial Park, China  +86 13451983657

+86 13451983657  sales@passioniot.com

sales@passioniot.com