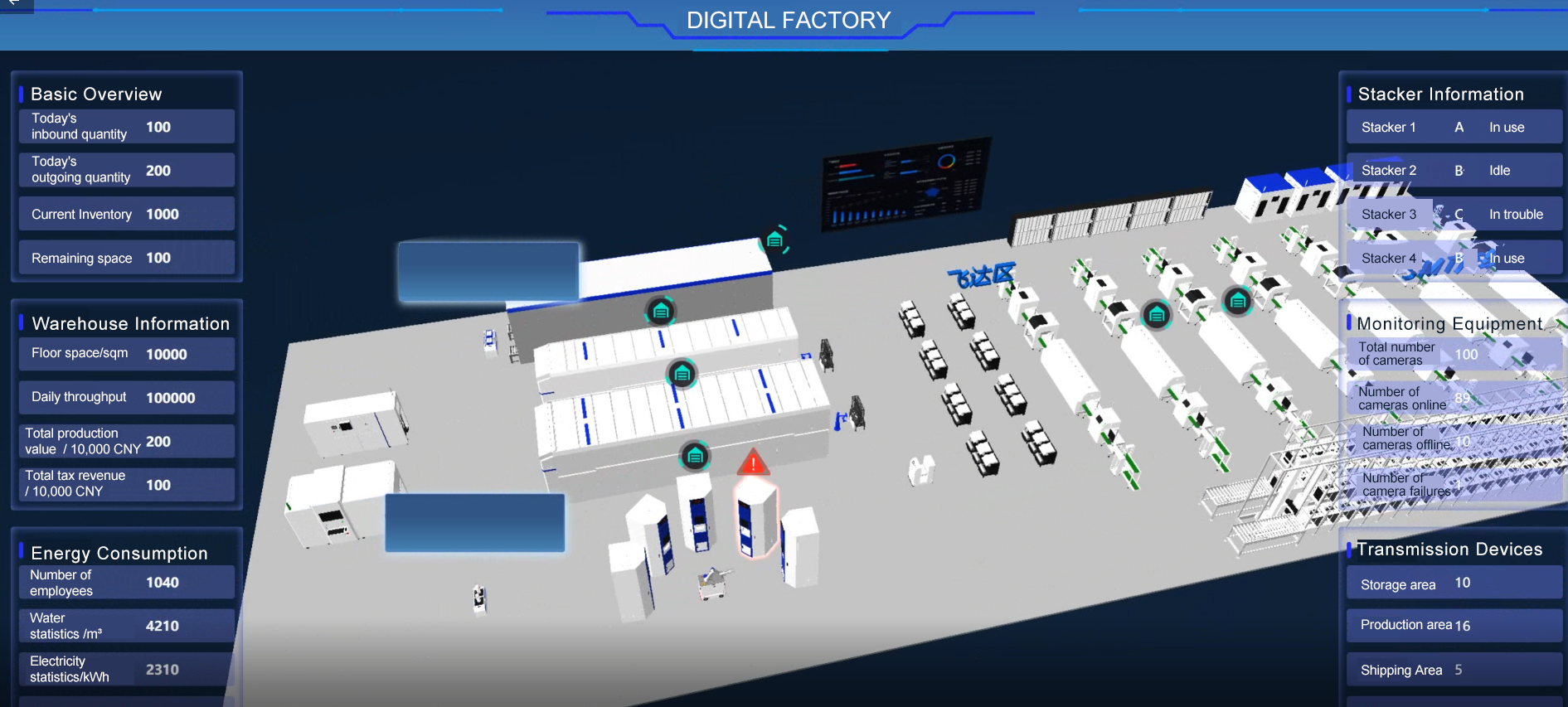

Digital Twin System for Smart Factory

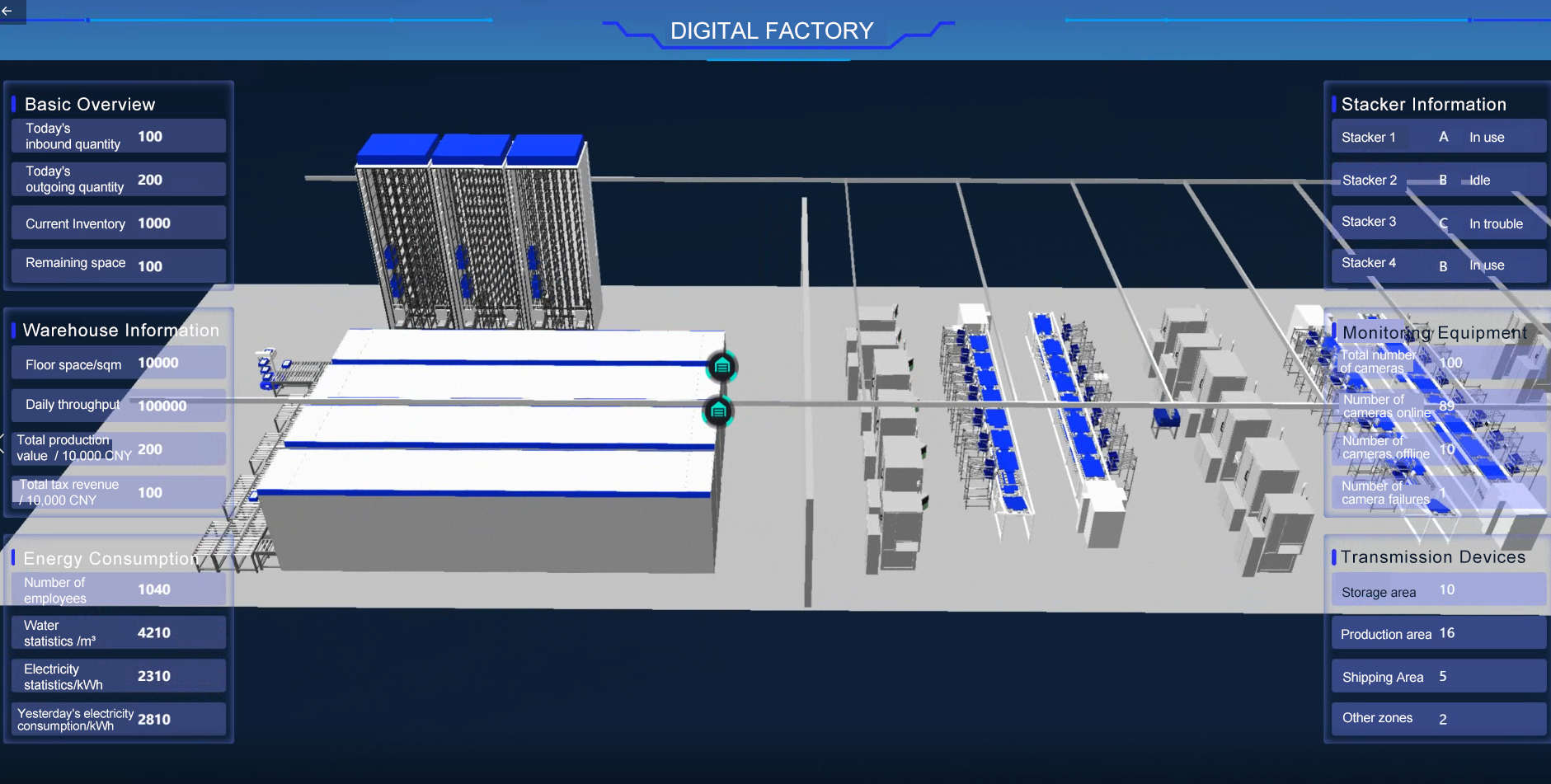

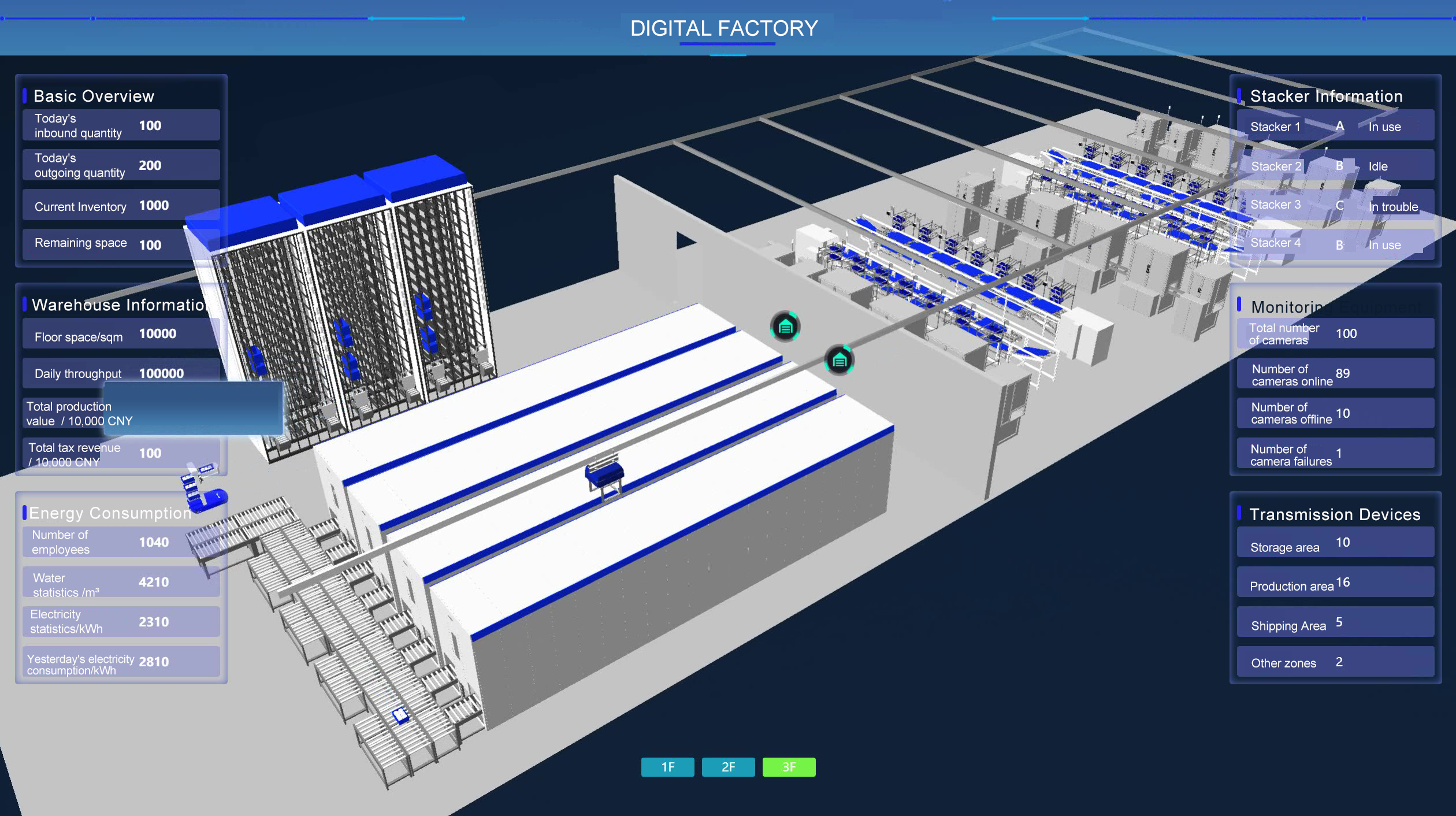

Passion’s digital twin platform is a real-time 3D visualization platform for intelligent warehouse built by combining technologies such as Digital Twin, BIM, GIS, AI and Big Data.

This platform mainly displays the actual workshop intelligent warehousing and logistics process in a three-dimensional dynamic way, and monitors the energy consumption and operation status of equipment in real time. In other words, you can grasp the overall warehouse operation situation through one screen.

Ø Flexibility and efficiency:

Information and data can be visualized and managed in real time, while executing optimal job assignment strategies for a flexible and efficient solution.

Ø Transparency of physical space:

Digital twin system platform that allows real-time monitoring of cargo storage status without any restrictions, fully releasing site flexibility.

Ø Break the management silo:

Our remote monitoring solution can quickly help clients to communicate information from corporate headquarters to the base factory.

Ø Component protection:

Through the temperature and humidity control of the storage environment to enhance the protection of moisture-sensitive components, thus avoiding improper control of materials affecting quality.

Ø Reduce costs and increase efficiency:

In the digital age, we can help manufacturing companies save labor, improve efficiency and control costs by creating smart warehousing.

No. 28 Heshun Road, Suzhou Industrial Park, China

No. 28 Heshun Road, Suzhou Industrial Park, China  +86 13451983657

+86 13451983657  sales@passioniot.com

sales@passioniot.com