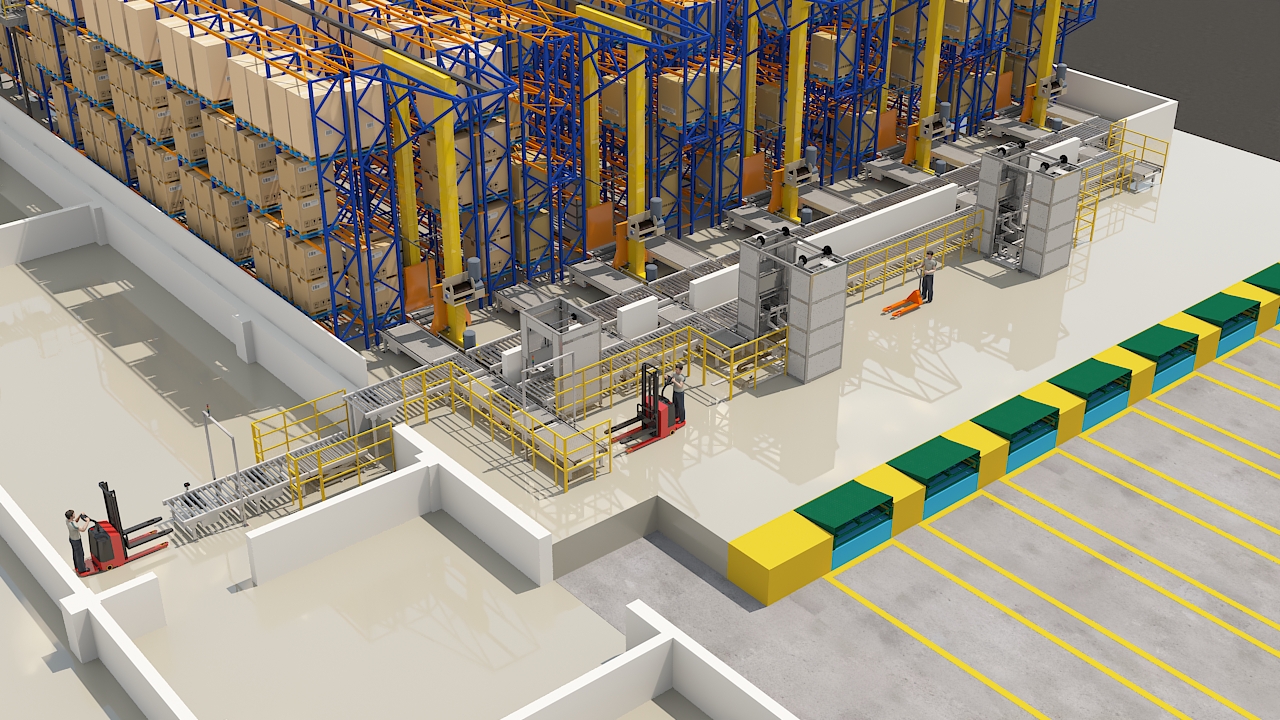

Product Description

- Passion’s automatic stereoscopic warehouse for finished products (AS/RS) has integrated Passion’s smart warehousing and logistics central control platform, intelligent storage equipment and automatic logistics equipment. It is a complete set of intelligent automatic stereoscopic warehouse of finished products, which is designed based on customers’ demands and consists of various types of warehouse management software, graphic monitoring and scheduling software, bar code recognition and tracking system, transfer robot, AGV trolley, goods sorting system, stacker addressing system, stacker control system and goods allocation detector. It can finish depositing and withdrawing unit goods automatically under the control of smart warehousing and logistics central control platform.

Product features

Compared with traditional warehouse, it is superior in the following aspects: High space utilization rate, high storage efficiency, real-time and precise system management, labor saving and avoiding inactive stock.

Product parameters

|

CATEGORY |

PRODUCT PARAMETERS |

|

Mode |

Custom |

|

Structural form/Goods typel |

Dual-column ground supporting straight dual-fork and dual-retractable fork, single goods |

|

Running speed |

Customized /600kg |

|

Motor brand/power |

Horizontal:4-150m/min,Elevating:0-30m/min, Fork:0-30m/min |

|

Positioning/resetting precision |

SEW,Horizontal:5kW,Elevating13kW,Fork:0.75kW |

|

Power supply mode |

Horizontal、Elevating:±5mm,Fork:±5mm |

|

Operating mode |

Safety slide wire, 3-phase 4-wire |

|

Addressing mode |

Maintenance,manual, automatic and online automatic |

|

Control mode of stocker |

Horizontal: laser; Vertical: bar code; Fork: proximity switch |

|

Driving mode of motor |

PLC(Mitsubishi FX/Siemens series) |

|

Power supply |

Frequency control |

|

Operation mode |

AC 380V 50Hz |

|

Communication mode |

Single and combined circulation |

|

Working noise |

Industrial wireless communication |

|

Ambient temperature and

relative humidity

|

≤80dB |

|

Body color |

-5~40℃, smaller than 90(Non-condensing) |

No. 28 Heshun Road, Suzhou Industrial Park, China

No. 28 Heshun Road, Suzhou Industrial Park, China  +86 13451983657

+86 13451983657  sales@passioniot.com

sales@passioniot.com